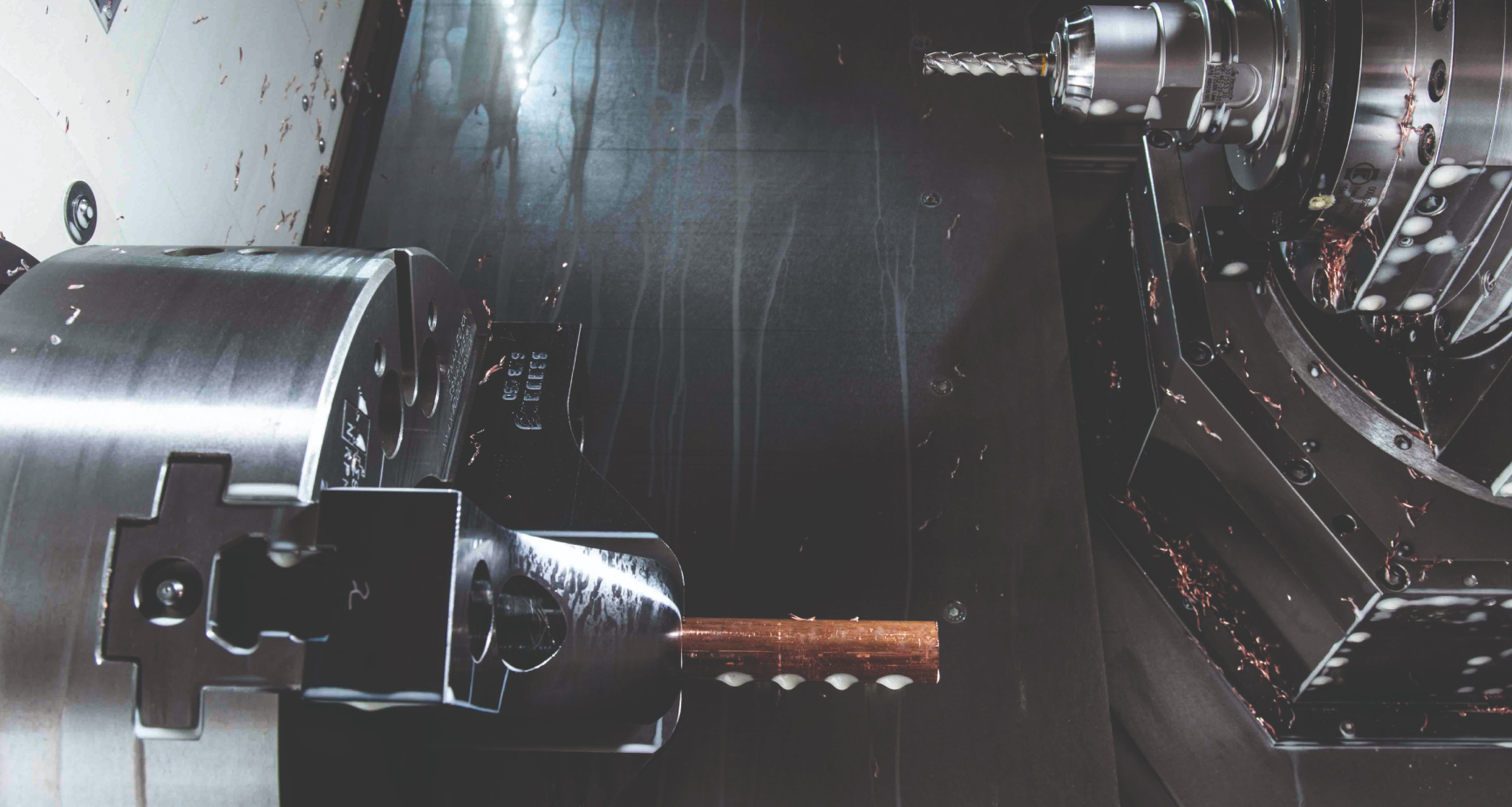

Turning – Precision in Every Rotation

Turning is a key component of our machining portfolio, enabling the precise production of rotationally symmetrical components. With our state-of-the-art machinery and experienced team, we offer accurate, efficient, and flexible turning processes that are perfectly tailored to meet our customers’ requirements. Whether single parts or series production – we always deliver the highest quality.

Maximum Precision:

Our CNC lathes ensure exact dimensional accuracy and repeatability through cutting-edge control technology. Even complex geometries and tight tolerances are implemented with precision, ensuring that the workpieces perfectly meet the specifications.

Versatile Machining Capabilities:

We process a wide range of materials, including steels, light metals, plastics, and special alloys. Thanks to our flexibility, we can produce both simple and complex turned parts – from small precision components to larger workpieces.

Efficiency and Quality:

By using automated processes, we achieve high productivity while maintaining consistent quality. Our focus on the optimal use of raw materials and minimizing tool wear also contributes to cost efficiency.

Custom Solutions:

We work closely with our customers to develop tailor-made solutions for specific requirements. Whether prototypes or large-scale production – our turning processes are flexibly scalable, allowing for quick adjustments.

With our expertise and state-of-the-art turning technology, we offer solutions that meet the highest demands for precision, quality, and efficiency. Every component that leaves our facility is crafted with the utmost care – perfect down to the last detail.

Contact us

Contact us for a non-binding offer.