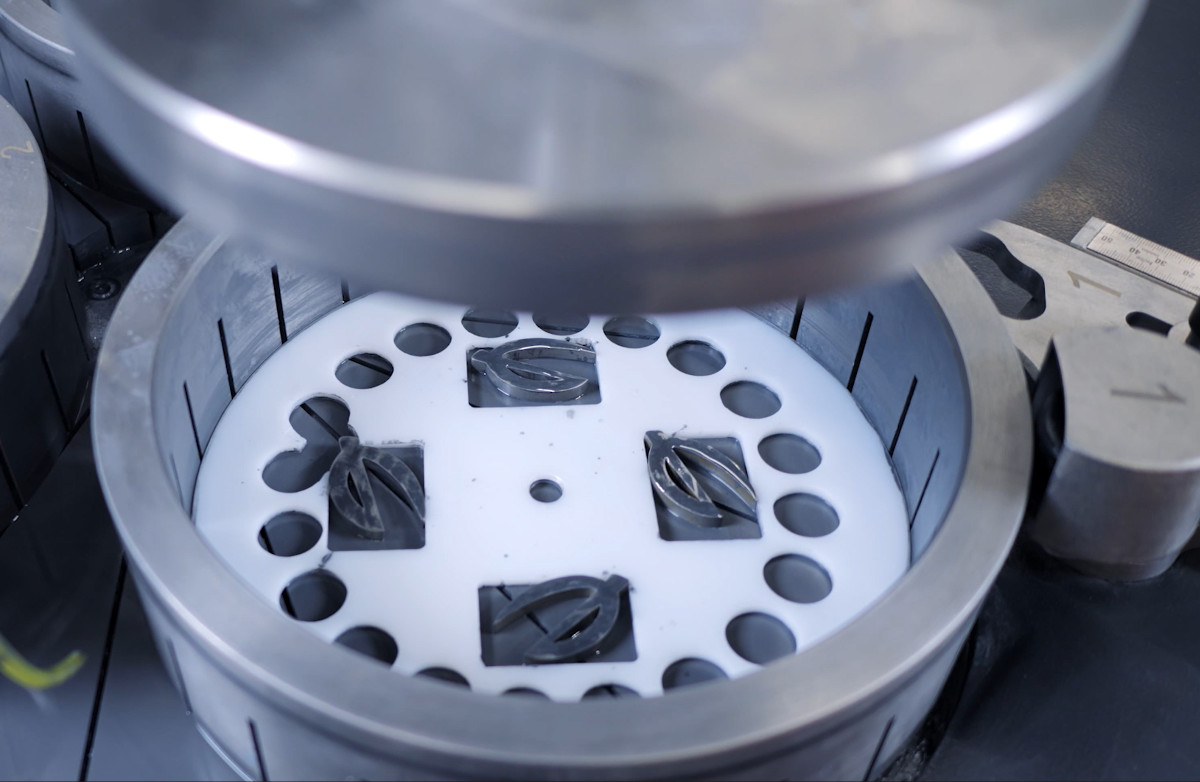

Lapping – precision at the highest level

Lapping is a high-precision finishing process that we use for the final machining of workpieces in order to achieve excellent surface quality and the tightest tolerances. This chipless process is based on an abrasive process in which fine abrasive grains are embedded in a lapping fluid between the workpiece and the lapping disc. Controlled relative movements smooth out the unevenness of the surface and remove material with microscopic precision.

Advantages of lapping:

Highest precision

Lapping enables extremely tight dimensional tolerances and ensures absolutely flat and uniform surfaces.

Excellent surface quality

With roughness values down to the nanometer range, lapping is suitable for demanding applications where optical or functional requirements are placed on the surface.

No thermal or mechanical stress

Since this is a purely abrasive process, the workpiece is neither thermally nor mechanically stressed during processing.

Versatile materials

Lapping can be applied to a wide variety of materials, from metals and ceramics to glass and plastic.

This process is ideal for components that are used in areas such as precision engineering, optics or aerospace and require extreme precision. With our modern machinery and many years of experience, we guarantee you results of the highest quality – perfectly tailored to your individual requirements.

Contact us

Contact us for a non-binding offer.