Deburring – perfection down to the last detail

Deburring is an essential step in our machining process to ensure the quality and functionality of components. We remove burrs and sharp edges that may arise during production to ensure a flawless surface and precise geometries. Depending on the requirements, we use various deburring processes, each of which is optimally tailored to the material and component geometry.

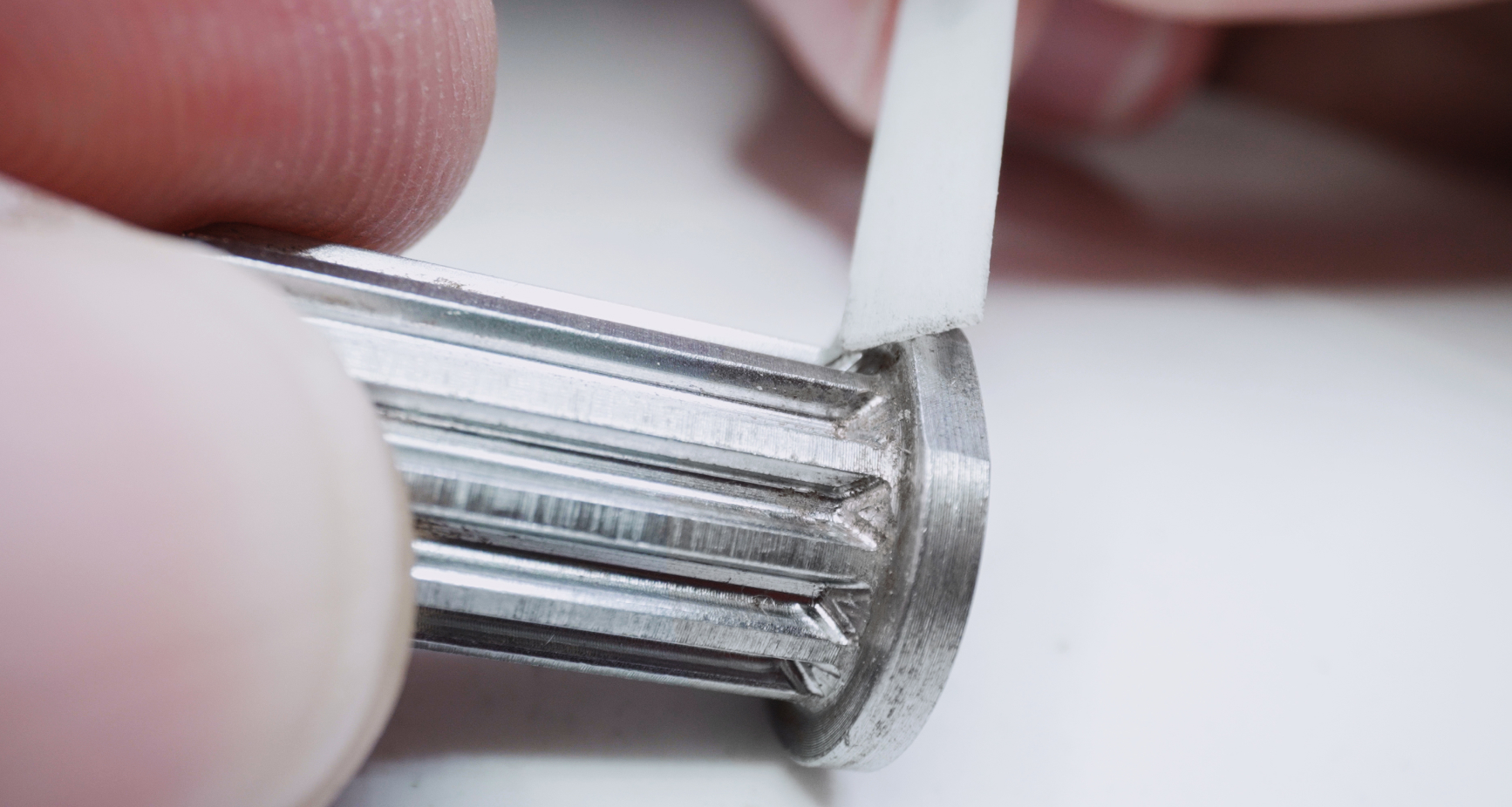

Manuel deburring

Manual deburring involves reworking the surface by hand using special tools. This method is particularly suitable for delicate or hard-to-reach areas that require a high level of precision. Our experienced specialists guarantee consistently high quality through their craftsmanship and ensure that every detail meets the requirements.

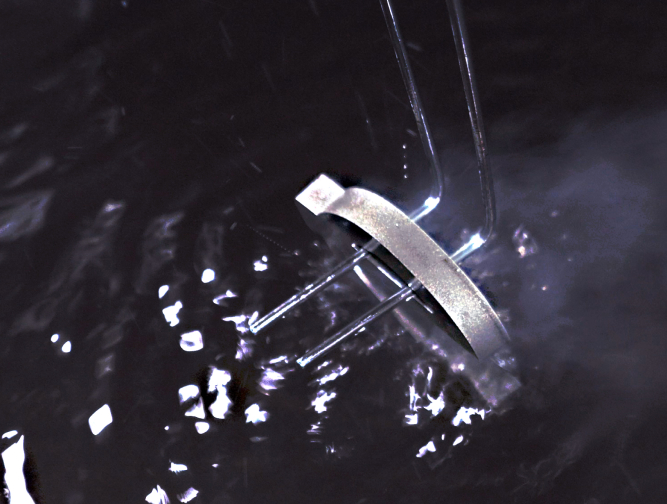

Magnetic deburring

We use magnetic deburring for smaller components and series. The workpieces are placed in a magnetic field in which magnetized grinding wheels rotate and reliably remove the burrs. This process is particularly efficient and is suitable for uniformly processing many components in a short time without mechanically stressing the workpieces.

Plasma polishing

Plasma polishing is an advanced electrochemical process that uses a plasma electrolyte to remove burrs at the atomic level. The process is ideal for components that have the highest demands on surface quality and precision. Plasma polishing not only ensures burr-free workpieces, but also gives the surfaces excellent smoothness and corrosion resistance.

With our combination of manual, magnetic and state-of-the-art plasma-assisted deburring processes, we ensure that every component is perfectly deburred and optimally prepared for further use.

Contact us

Contact us for a non-binding offer.